Location:Home Page > Archive Archive

Why can't copper and aluminum wires be twisted together when wiring?

2023-03-18【Archive】

Briefly about advantages and disadvantages of copper and aluminum wire:

With same area, load on copper wire is greater than on aluminum one. Copper wire is more flexible than aluminum wire. Copper wire has a lower resistivity than aluminum wire. Copper wire is more stable than aluminum wire.

However, copper wire is about 3.5 times more expensive than aluminum. Therefore, many people prefer to use aluminum wires to save money, but editor still strongly recommends copper wires, you can’t save money on this!

If some friends used aluminum wires first, they later bought copper wires. So is it possible to directly connect copper wire and aluminum?

Answer: No.

Why can't copper and aluminum wires be connected together?

1.The potentials of copper and aluminum are different, and copper-aluminum contact part will accelerate oxidation of aluminum wire due to reaction of primary battery.After a long time, the copper-aluminum connection will have poor contact.

If you want to connect them together, you must use copper and aluminum adapter clamps or adapter tubes.

▲ Copper-aluminum adapter clamp

2. This is a chemical problem. The chemical properties of metals are relatively active and inactive. For example, gold never rusts, which means that gold is chemically inactive. Iron rusts easily, and iron is more active than gold. .If two metals are connected together, oxidation of active metal will be accelerated. Compared to copper, aluminum is more active. Connecting two cables will accelerate oxidation of aluminum (that is, rust), which will affect use.

3. When copper and aluminum conductors are directly connected, contact surface of two metals easily forms an electrolyte under influence of moisture, carbon dioxide and other impurities in air, thus forming a negative electrode with aluminum and a positive electrode with copper aluminum galvanic corrosion, resulting in an increase in contact resistance at site compounds of copper and aluminum.

▲ Copper and aluminum wire connector

In addition, due to large difference between modulus of elasticity and coefficient of thermal expansion of copper and aluminum, after many cooling and heating cycles (power on and off), a large gap will form at contact point during operation and affect contact. Contact resistance also increases. An increase in contact resistance will cause an increase in temperature during operation.

Corrosion and oxidation will increase at high temperature, leading to a vicious circle, further deterioration of connection quality, and finally, too high a temperature of contact point, and even accidents such as smoking and fire.

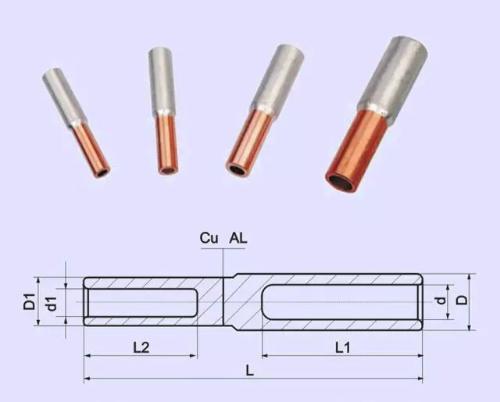

▲ Copper-aluminum adapter

Why use copper-aluminum adapters when connecting copper and aluminum wires?

1. The off-white substance generated at junction of copper wire and aluminum wire is Al2O3 for a long time, and contact resistance at junction will increase and generate heat, causing circuit to turn on and off from time to time. which can easily cause a fire in a building.

Therefore, use a special copper-aluminum adapter. Avoid unnecessary problems!

▲ Copper-Aluminum Splicing Device (commonly known as "Cu-Aluminum Ferrule")

2. If copper wire and aluminum wire are connected directly, connection is easily oxidized, resulting in an increase in resistance, which makes it easier to burn out. The real reason for this damage is that aluminum element is more active than copper element, and many micropotentials (such as microbatteries) will be generated on copper-aluminum junction surface, leading to microelectrical corrosion. , and contact resistance will increase with time.

In normal housework, it's safer to tin the copper first and then join it together.

3. In power supply system, copper and aluminum are directly connected, and when current flows, galvanic corrosion will occur. Therefore, a copper-aluminum junction should be used, or a sheet of tin should be placed in middle of contact surface, and a layer of conductive paste should be applied if possible. When connecting in a normal household, copper wire can be tinned and then connected to aluminum wire to avoid galvanic corrosion.

Related

- Why can't copper and aluminum wires be twisted together when wiring?

- Why can't crystal oscillator be placed on edge of the PCB?

- Case analysis! Why can't crystal oscillator be placed on edge of PCB?

- PCB design guidelines: safety regulations, layout and wiring, EMC, thermal design, process engineering.

- You can't think about it, can you? A small resistor can be great too

- Is printed circuit board covered with copper very “up to mark”? One article to help you get practical guidelines and norms

- Why are processors square and not round?

- Does PCB use copper mesh or solid copper, are you using it correctly?

- Why is electricity divided into AC and DC?

- Why are there always two capacitors in circuit 0.1uF and 0.01uF?

Hot Posts

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

- What is drowning in gold? Why Shen Jin?

- This is a metaphor for EMI/EMS/EMC that can be understood at a glance.

- How many types of pads have you seen in PCB design?

- Summary of Common PCB Repair Techniques

- What is three anti-paint? How to use it correctly?

- Knowing these rules, you will not get confused looking at circuit diagram.

- How to make anti-interference PCB design?

- Can diodes do this?