Location:Home Page > Archive Archive

What is three anti-paint? How to use it correctly?

2023-03-30【Archive】

01 What is conformal paint?

Conformal anti-paint is a specially formulated coating used to protect printed circuit boards and associated equipment from environmental erosion. Conformal paint has good resistance to high and low temperatures; after curing, it forms a transparent protective film, which has excellent insulation, moisture resistance, airtightness, shock resistance, dust resistance, corrosion resistance, aging resistance, corona discharge. resistance and other properties.

Under real-world environments such as chemical environments, vibration, high dust, salt fog, humidity, and high temperatures, PCBs may experience corrosion, softening, deformation, mold, and other problems that cause PCBs to malfunction.

A three-layer paint is applied to surface of PCB, forming a layer of three-protection protective film (tri-resistant paint refers to protection against moisture, salt fog, and mold).

Under conditions such as chemicals (such as fuel, coolant, etc.), vibration, humidity, salt spray, humidity, and high temperatures, an uncoated PCB may corrode, mold, short circuit etc., leading to failure of circuit, use of conformal ink can protect circuit from damage, thereby increasing reliability of printed circuit board, increasing its margin of safety and ensuring its service life.

Besides, since conformal coating prevents leakage, it provides higher power and shorter PCB spacing. Thus, goal of component miniaturization can be achieved.

02 Specifications and requirements for three paint protection processes

Painting requirements:

1. Paint Thickness: Paint film thickness is controlled at 0.05-0.15mm. Dry film thickness 25 µm-40 µm.

2. Secondary Coating: In order to ensure thickness of products with high protection requirements, secondary coating can be carried out after paint film has cured (determine whether to perform secondary coating according to requirements).

3. Inspection and Repair: Visually check if coated PCB meets quality requirements and fix problem. For example, if pins and other protective areas are smeared with conformal paint, use cotton ball degreaser tweezers or clean cotton balls soaked in whiteboard water to wipe them clean. Be careful not to wash off normal film of paint when cleaning.

4. Replacing components: after paint film has cured, if you want to replace components, you can do following:

(1) Solder components directly to electric ferrochrome, and then use a cotton cloth soaked in water to flush board to clean substances around pad

(2) Welding replacement parts

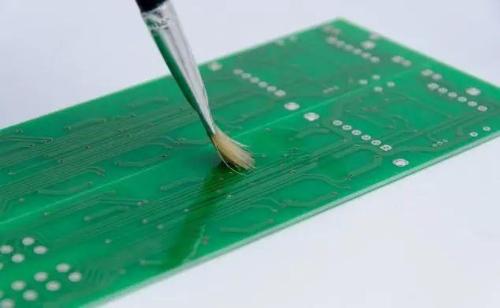

(3) Use a brush dipped in three anti-paints to paint welding part, and let surface of paint film dry and harden

Action Requirements:

1. The three paint protection workstations must be clean and dust-free, with no flying dust. Good ventilation must be provided and unauthorized personnel must not enter.

2. During work, wear masks or gas masks, rubber gloves, chemical goggles and other protective equipment so as not to harm body.

3.After finishing work, used tool must be cleaned in time, and container with protective paint should be closed and tightly closed.

4. PCBs must be anti-static and PCBs must not overlap. PCBs must be horizontal during coating.

Quality requirements:

1. The surface of printed circuit board must not have paint flows or drips. When painting with a brush, be careful not to drip onto a partially insulated part.

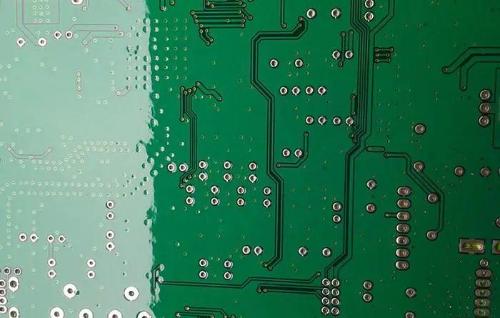

2. The three layers of paint protection should be flat, bright, uniform in thickness, and protect surface of pads, SMD components, or conductors.

3. There must be no bubbles, pinholes, ripples, shrinkage cavities, dust and other defects and foreign objects in contact with paint film on surface of paint layer and parts.

4. Partially insulated components or areas cannot be covered with protective paint.

03 Parts and devices that must not be coated with protective paint

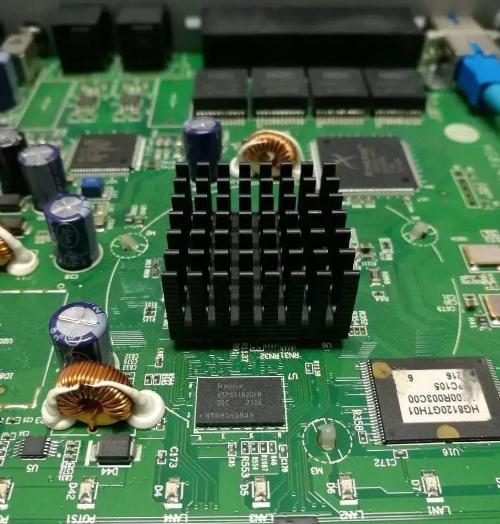

(1) Common uncoated devices: power heat sink paint, heat sinks, power resistors, power diodes, cement resistors, switches, potentiometers (adjustable resistors), buzzers, battery holders, fuse holders, microcircuits. holders, tact switches, relays and other types of sockets, pin headers, terminal blocks and DB9, push-in or SMD LEDs (non-indicating), digital tubes and ground screw holes.

(2) Parts and devices shown in drawings, on which conformal paint cannot be applied.

(3) According to detailed description of "Catalog of Impossible Conformal Anti-Corrosion Components (Region)", devices that cannot use conformal anti-corrosion paint.

If conventional uncoated devices are required by regulations to be coated, they can be coated with a three-layer coating in accordance with requirements specified by R&D department or indicated on drawings.

04 Precautions for spraying tri-resistant paint are as follows

1.PCBA must have a technological edge and a width of at least 5 mm, so that it is convenient to enter machine and drive along track.

2. The maximum length and width of PCBA board is 410*410mm, and the minimum is 10*10mm.

3. The maximum height of PCB-mounted components is 80 mm.

4. The minimum distance between painted and unpainted area of components on PCB is 3mm.

5. Thorough cleaning can ensure complete removal of corrosion residues and good adhesion of three anti-paints to PCB surface. The paint thickness is preferably 0.1-0.3 mm. Baking conditions: 60°C, 10-20 minutes.

6. In spraying process, some components cannot be sprayed, such as: high power cooling surface or heat sink components, power resistors, power diodes, cement resistors, dial switches, adjustable resistors, cell alarm, battery holder, insurance holder (tube), IC holder, clock switch, etc.

05 Introduction to Conformal PCB Ink Recycling

When PCB needs to be recycled, expensive components on PCB can be removed individually and rest discarded. But most commonly used method is to remove all or part of protective film from PCB and replace damaged components one by one.

When removing three paint protection films, make sure that they do not damage substrate under component, other electronic components, structures near repair site, etc. The methods for removing the protection film mainly include: using chemical solvents, micro-grinding, mechanical methods and soldering through a protective film.

Use of chemical solvents is most commonly used method for removing protective film of three anti-paints. Its essence lies in chemical properties of protective film to be removed and chemical properties of specific solvent.

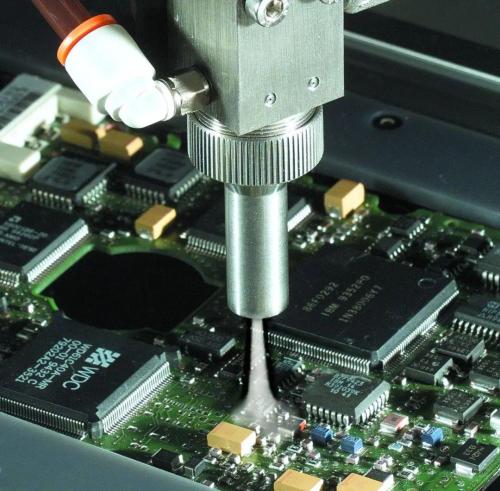

Microgrinding is use of high-speed particles ejected from a nozzle to "grind" protective film of tri-color paint on a printed circuit board.

Mechanical method is easiest way to remove protective film of conformal paint. Soldering through protective film is to first open outlet hole in protective film so that molten solder can be released.

Related

- What is three anti-paint? How to use it correctly?

- What is a supercapacitor? How is it different from conventional capacitors?

- What is power supply ripple, how to measure their magnitude and how to suppress?

- Does PCB use copper mesh or solid copper, are you using it correctly?

- How to make anti-interference PCB design?

- Anti-reverse connection is very important, make good use of these 4 commonly used circuits

- Three circuit diagrams to teach you how to understand how a buck RC works

- How to effectively use an oscilloscope? Even senior engineers overlook these details...

- How to solve the problem with electrostatic discharge? Use several real cases to conduct a joint analysis

- About resistors, this is what you need to know

Hot Posts

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

- What is drowning in gold? Why Shen Jin?

- This is a metaphor for EMI/EMS/EMC that can be understood at a glance.

- How many types of pads have you seen in PCB design?

- Summary of Common PCB Repair Techniques

- What is three anti-paint? How to use it correctly?

- Knowing these rules, you will not get confused looking at circuit diagram.

- How to make anti-interference PCB design?

- Can diodes do this?