Location:Home Page > Archive Archive

Deciphering power supply circuit of LED drive in detail

2023-11-26【Archive】

1. What is an LED

LEDs (light emitting diodes), also known as light emitting diodes, use solid semiconductor chips as light emitting materials. When a forward voltage is applied to both ends, carriers in semiconductor recombine, releasing excess energy and causing photons to be emitted. Produces visible light.

Secondly, what are advantages of LEDs

High efficiency and energy saving Only a few kilowatt-hours of electricity are consumed in 1000 hours (conventional 60W incandescent lamps consume 1 kilowatt-hour of electricity in 17 hours, and conventional 10W energy-saving lamps consume 1 kilowatt-hour of electricity for 100 hours)

The ultra-long life semiconductor chip emits light, does not contain filament, does not contain glass bubbles, is not afraid of vibration, is not easy to be broken, and service life can reach 50,000 hours (the life of ordinary incandescent lamps is only 1000 hours, and life of ordinary energy-saving lamps is only eight thousand hours)

Healthy light The light does not contain ultraviolet and infrared rays and does not emit (normal light contains ultraviolet and infrared rays)

Green environmental protection does not contain harmful elements such as mercury and xenon, which is conducive to recycling and disposal, and does not generate electromagnetic interference (conventional lamp tubes contain elements such as mercury and lead, and electronic ballasts in energy-saving lamps will create electromagnetic interference)

Protection of vision. DC drive, no strobe (ordinary flashlights are powered by AC, this will inevitably lead to strobe)

High light output and low heat generation: 90% of electrical energy is converted into visible light (80% of electrical energy of conventional incandescent lamps is converted into heat energy, and only 20% of electrical energy is converted into light energy)

High safety factor, less voltage and current required, less heat generation, no potential safety hazard, can be used in hazardous areas such as mines

Great market potential. Can be used low-voltage DC power supply, battery, solar power, and can also be used in remote mountainous areas, field lighting and other places where electricity is scarce and less electricity.

3. Problem Solving Method and Feasibility Analysis

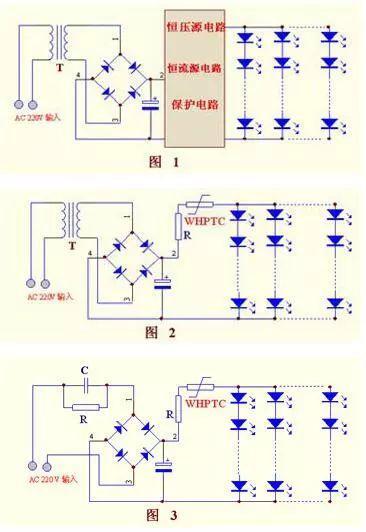

The solution is self-healing WHPTC overcurrent protection component. If WHPTC overcurrent protection device is used for protection, it will be a different result. From principle, when current in circuit exceeds specified value, it will automatically quickly protect and automatically reset after troubleshooting, without manual replacement. For LEDs, a change in voltage is not direct cause of LED damage, but an increase in current is real killer of LEDs.

Obviously, using this WHPTC feature has an absolute advantage in protecting LED circuit, making a simple power supply a reality. Practice has proven that it is effectively protected up tofailure of LED circuit. On a simple power supply, this advantage is especially noticeable. From analysis of following figure 3, it can be seen that constant current and constant voltage circuits can be eliminated with WHPTC, and quality of LED is also improved. Device cost, manufacturing cost, failure rate, maintenance cost, etc. are greatly reduced. The market competitiveness of products has also increased significantly. So whoever uses WHPTC first will take over market first.

Fourth, topology comparison before and after using WHPTC

Talking about aging of LED products When we use LEDs, we often have such problems. When LEDs are welded to products, they work normally at first, but after a while, dark light, flickering, and malfunctions appear. , Intermittent lighting and other phenomena may cause serious damage to product. The reasons for this phenomenon are approximately following:

1. When applying products, there are problems in soldering process, such as soldering temperature is too high and soldering time is too long, and anti-static work is not performed properly. More than 95% of these problems are caused by packaging process.

2. This is due to quality of LED itself or manufacturing process. Prevention methods:

1. Have good control over welding process.

2. Conduct a product aging test.

Aging is an important guarantee of reliability of electronic products and last necessary step in their production. LED products can improve performance after aging, and help stabilize performance in subsequent use. LED aging testing is a very important link in product quality control, but in many cases it is often neglected, and it is not possible to carry out correct and effective aging. LED aging test is a countermeasure based on characteristics of product failure rate curve, that is, bath curve, to improve product reliability, but this method is not necessary, after all, aging test is to sacrifice lifetime of a single LED product for price.

LED aging methods include constant current aging and constant voltage aging. A constant current source means that current is constant at all times. If there's a frequency issue, it's not DC. This is an alternating or pulsating current. An AC or pulsating current source may be designed to have a constant rms value, but such a power source cannot be called a "constant current source".

DC aging is most suitable for LED current performance. ED aging method; overcurrent aging is also a new aging method adopted by manufacturer. Using a constant current source with adjustable frequency and current. aging is done to evaluate quality and life expectancy of LEDs in a short time, and can reveal many latent LEDs that cannot be detected by normal aging. The PTC thermistor used as LED current limiter effectively prevents high temperature failure. In recent years, development of Light Emitting Diodes (LEDs for short) has made significant progress, from being used solely as indicator lamps to high-power LEDs with a luminous flux of over 100 lumens.

Soon cost LEDiodine lighting will drop to a level similar to cost of traditional cold cathode fluorescent lamps, or CCFL for short. This has led to increased interest in following LED applications: automotive lighting, indoor and outdoor LED light sources, and LCD backlighting for laptops or TVs. The development of high power LED technology has increased requirements for heat dissipation during design phase. Like all other semiconductors, LEDs should not overheat, so as not to accelerate decrease in output power or, in worst case, complete failure. Compared to incandescent lamps, although high-power LEDs are more efficient, a significant portion of input power is still converted into heat instead of light energy.

Thus, good heat dissipation and consideration of high temperature conditions at design stage are required for reliable operation. When calculating LED control circuit, temperature must also be taken into account: its forward current must be chosen in such a way that LED chip does not overheat even when ambient temperature reaches its maximum values. When temperature rises, it is necessary to reduce maximum allowable current, that is, reduce nominal value, achieve cooling. LED manufacturers include derating curves in their product specifications. See Figure 1 for such curves.

5. Why is it better to use LEDs for corridor lighting?

1. At present, price of LEDs is relatively high. Corridor lighting is a common object, and everyone can share responsibility.

2. Currently, incandescent lamps are commonly used in corridors. If LED lamps are used instead, energy saving effect will be especially noticeable.

3. The light in hallway is off during day. Run or turn off frequently at night. Not to mention energy-saving lamps, even incandescent lamps will soon run out. But this is not scary for an LED lamp, because its light-emitting mechanism differs from that of incandescent lamps and energy-saving lamps.

4, LED lamps have a long service life, which avoids awkward situation when you often have to repair corridor lamps.

5. The light in hallway is an electricity fee paid by management company. Investments are one-time. Saving 80% on electricity bills is long term and property management department is most cost effective.

6. Can LED lights directly replace current corridor lights?

No. Since hallway lights that everyone now uses are incandescent bulbs, it is not possible to replace them with LED or energy-saving lamps, so if you want to switch to LED lights, you must use sound and light switches at same time. . Now there is spaCentral built-in LED corridor lighting with sound and light control, which directly uses 220V power supply, which is very convenient to use. We highly recommend use of 24V DC corridor lights, and its benefits and reasons will be presented in another article. With development of technology and decreasing cost, LED lamps will inevitably replace energy-saving lamps.

7. Classification and characteristics of LED drive power

1 can be divided into two categories depending on how you drive:

(1) Constant flow:

a. The output current of DC drive circuit is constant, but DC output voltage varies within a certain range depending on load resistance. The lower load resistance, lower output voltage and higher load resistance. The more, higher output voltage;

b. The DC circuit is not afraid of a short circuit of load, but it is strictly forbidden to completely open load.

c. It is ideal to drive an LED with a constant current driving circuit, but cost is relatively high.

d. Pay attention to maximum withstand current and voltage value, which limit number of LEDs used;

(2) Regulated voltage:

a. When determining parameters in voltage stabilization circuit, output voltage is fixed, and output current changes with increasing or decreasing load;

b. The voltage stabilization circuit is not afraid of a break in load circuit, but it is strictly forbidden to completely short circuit load.

c. To drive LEDs with a voltage regulated control circuit, each string must be equipped with a suitable resistor so that each string of LEDs displays an average brightness;

d. The brightness will be affected by voltage changes from rectification.

2. Classification by schema structure

(1) Resistor and capacitor pull down method: When capacitor pulls down while flashing, due to effect of charge and discharge, instantaneous current through LED is very large, which is easy to damage chip. Sensitivity to voltage fluctuations in network, low energy efficiency and low reliability.

(2) Resistor drop method: By dropping resistance, mains voltage changes are greatly perturbed, it is not easy to make a stabilized power supply, and pull-down resistor consumes most of power, so this power supply method, efficiency is very low, and reliability of system is also low.

(3) Conventional step-down transformer method: power supply is small in size, heavy in weight, and efficiency of power supply is low, generally only 45% to 60%, so it is rarely used and reliability is not high.

(4) Electronic transformer step-down methodA: The power supply efficiency is low, voltage range is small, generally 180-240V, and ripple interference is large.

(5) Buck-mode RCC switching power supply: The voltage regulation range is relatively wide, and efficiency of power supply is relatively high. Generally, it can reach 70% to 80%, and it has a wide application range. Because oscillation frequency of this control method is intermittent, switching frequency is not easy to control, load voltage ripple ratio is relatively large, and abnormal load adaptability is poor.

(6) PWM control mode switching power supply: mainly consists of four parts, input rectification filter part, output rectification filter part, PWM voltage regulation control part, switching power conversion part. The basic working principle of PWM switching voltage regulation is that in event of a change in input voltage, internal parameters and external load, control circuit performs feedback feedback on difference between controlled signal and reference signal to adjust pulse width. main circuit switching device. Make output voltage or current of switching power supply stable (that is, appropriate regulated power supply or DC power supply). The efficiency of power supply is extremely high, typically 80% to 90%, and output voltage and current are stable. As a rule, such a circuit has excellent protection measures, which ensures high reliability of power supply.

It can be seen from above introduction that LED power supply designed with PWM control method is ideal LED power supply.

Related

- Deciphering power supply circuit of LED drive in detail

- (In-depth long text) Detailed interpretation of switching power supply circuit

- Detailed explanation of commonly used LED drive power

- Analysis of damping RC circuit of a switching power supply "haberdashery"

- A detailed explanation of three commonly used LED drive power schemes.

- Practical Skills: Explain steps of circuit board puzzle in detail.

- One article to understand design of DC power supply circuit modules.

- The composition of switching power supply circuit and a detailed explanation of general circuits

- Circuit Analysis of 6 Examples Explaining Lightning Surge Protection in Detail

- Explain in detail why a switching power supply should be connected to an equivalent load.

Hot Posts

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

- What is drowning in gold? Why Shen Jin?

- This is a metaphor for EMI/EMS/EMC that can be understood at a glance.

- How many types of pads have you seen in PCB design?

- Summary of Common PCB Repair Techniques

- What is three anti-paint? How to use it correctly?

- Knowing these rules, you will not get confused looking at circuit diagram.

- How to make anti-interference PCB design?

- Can diodes do this?