Location:Home Page > Archive Archive

A detailed explanation of three commonly used LED drive power schemes.

2023-04-18【Archive】

There are many types of LED power supplies, and quality and price of different power supplies vary greatly, which is also one of important factors affecting quality and price of product. LED drive power can generally be divided into three categories: one is a switching DC power supply, another is a linear IC power supply, and third is a step-down power supply with resistance and capacitance.

01 DC switching

A transformer is used to convert high voltage to low voltage, and rectification and filtering are performed to obtain a stable low voltage DC current. Switching DC power supply is divided into isolated power supply and non-isolated power supply. Isolation refers to isolation of high and low output voltage, which is very safe, so shell insulation requirements are not high. The safety of non-insulated ones is somewhat worse, but cost is relatively low. Traditional energy-saving lamps use a non-isolated power source and are protected by insulating plastic shells. The safety of switching power supply is relatively high (generally, output is low voltage), and performance is stable. The disadvantage is complexity of circuit and high price. Switching power supply technology is mature and performance is stable, and is currently main power supply for LED lighting.

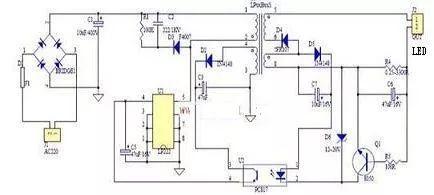

Figure 1. Switching power supply of an isolated DC fluorescent lamp

Figure 2: Schematic diagram of switching an isolated DC supply

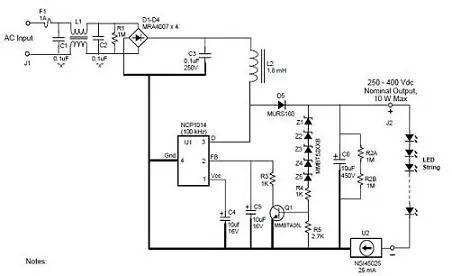

Figure 3. Switching DC power supply

Figure 4: Schematic diagram of switching a non-isolated DC supply

02 Linear power supply IC

One or more ICs are used for voltage distribution, there are several types of electronic components, very high power factor and energy efficiency, no electrolytic capacitor required, long life and low cost. The disadvantage is that high voltage output is not isolated, but strobe is, and case is required for protection against electric shock by isolation. The market claims that there are no (remove) electrolytic capacitors, and those with super long life use linear IC power supplies. The IC drive power supply has advantages of high reliability, high efficiency and low cost, and will become an ideal LED drive power supply in future.

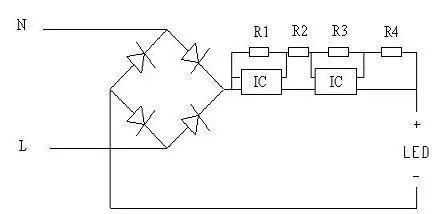

Figure 5: Linear power supply IC

Figure 6: Schematic diagram of a linear IC power supply

03 RC step-down power supply

A capacitor is used to provide control current by charging and discharging it. The circuit is simple and inexpensive, but its performance is poor and its stability is poor. It is easy to burn out LED when mains voltage fluctuates. , At same time, output high voltage is non-isolated, and an insulating protective shell is required. Low power factor, short life, generally only suitable for economical low power products (within 5W). For high power products, output current is large, and capacitor cannot provide large current, otherwise it is easy to burn out. In addition, country has requirements for power factor of high-power lamps, i.e. The power factor above 7W should be greater than 0.7, but power supply with step-down resistance and capacitance is far away. It cannot be achieved (usually between 0.2-0.3), so high power products should not use step-down RC source nutrition. On market, almost all low-end, low-demand products use step-down RC power supplies, and some high-end, cheap, low-cost products also use step-down RC power supplies.

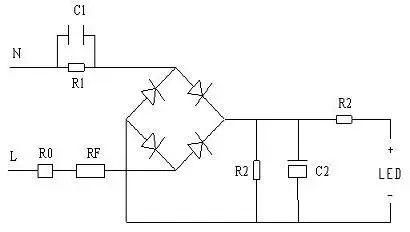

Figure 7: RC step-down power supply

Figure 8: Schematic diagram of an RC buck power supply

04 Energy Cost vs. Performance

Let's take 3W small light bulbs and 16W fluorescent tubes as an example. Comparison of cost of different power supplies:

It can be seen that difference in cost between different types of power supplies is very large, among which most expensive is a certified switch-isolated power supply, and cheapest is an RC step-down power supply.

Comparison of different power supplies:

In mid to high end market, switching non-isolated DC power supplies are still main power supplies in market, and it is common for manufacturers to incorporate high voltage isolation into design of structure. In entry-level market, most manufacturers use step-down RC power supplies, and some manufacturers use linear IC power supplies (requiring certain design options from manufacturers).

With different power supplies, performance and price of products vary. We must choose different products according to different markets.

Related

- A detailed explanation of three commonly used LED drive power schemes.

- Detailed analysis of the "various protection schemes" of a switching power supply

- [Comic] Detailed explanation of knowledge of power sources

- Does LED drive power need to be a constant current source?

- Analysis and comparison of 6 most commonly used DC power supply circuits

- A detailed explanation of role of pull-up resistors on triodes and MOS lamps.

- A list of some of the tools commonly used by electronic engineers.

- The triode is used as a switch. You should know function of these capacitors which are commonly used.

- Super practical! The 10 Most Commonly Used Power Supply Design Formulas

- Countdown of 8 most commonly used diodes

Hot Posts

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

- What is drowning in gold? Why Shen Jin?

- This is a metaphor for EMI/EMS/EMC that can be understood at a glance.

- How many types of pads have you seen in PCB design?

- Summary of Common PCB Repair Techniques

- What is three anti-paint? How to use it correctly?

- Knowing these rules, you will not get confused looking at circuit diagram.

- How to make anti-interference PCB design?

- Can diodes do this?