Location:Home Page > Archive Archive

How to choose a switching power supply - isolated or non-isolated

2023-12-06【Archive】

1. The concept of power isolation and non-isolation

Power supply isolation and non-isolation is mainly for switching power supply. The following is a common sentiment in industry:

①Isolated power supply: There is no direct electrical connection between input circuit and output circuit of power supply, input and output are in a high-impedance isolated state, and there is no current circuit.

②Non-isolated power supply: there is a DC loop between input and output, for example, there is a common ground between input and output.

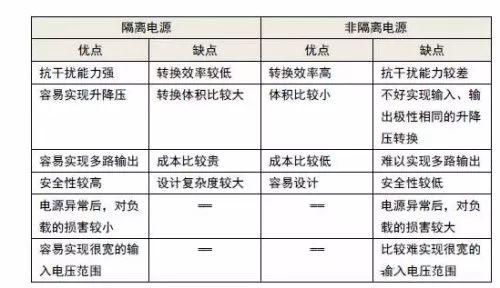

Second, advantages and disadvantages of isolated and non-isolated power supply

It can be seen from above concepts that for commonly used power supply topologies, non-isolated power supplies mainly include: buck, boost, buck-boost, etc., and isolated power supplies mainly include various types of flyback, forward, and half-bridge with isolating transformers., LLC and other topologies.

By combining commonly used isolated and non-isolated power supplies, we can intuitively get some advantages and disadvantages, and advantages and disadvantages of two are almost opposite.

In order to use isolated or non-isolated power supplies, you need to know what power requirements are for actual project, but before that, you need to understand main differences between isolated and non-isolated power supplies:

①The reliability of insulation module is high, but cost is high and efficiency is low.

②The structure of non-isolated module is very simple, cost is low, efficiency is high, and safety performance is low.

Therefore, it is recommended to use an isolated power supply in following cases:

①An isolated AC/DC power supply is required in cases where there is a risk of electric shock, such as disconnecting mains power and converting it to low-voltage DC;

②The serial communication bus transmits data through physical networks such as RS-232, RS-485 and controller network (CAN). Each of these interconnected systems is equipped with its own power supply, and each system is often spaced apart. Therefore, we usually need to isolate power supply for electrical isolation to ensure physical safety of system, and cut ground loop through isolation to protect system from transient high voltage surges and reduce signal distortion;

③For external I/O ports, in order to ensure reliable operation of system, it is also recommended to isolate power supply of I/O ports.

3. Use of isolated and non-isolated power supplies

By understanding advantages and disadvantages of isolated and non-isolated power supplies, we can see that each has its own advantages. For some commonly used built-in power supplies, we can already draw accurate conclusions:

①For front stage power supply of system, in order to improve anti-interference performance and ensure reliability, an isolated power supply is generally used.

② A microcircuit or part of a circuit on a printed circuit board provides power. In terms of value for money, non-isolated solutions are preferred.

③ In cases where safety is required, if AC/DC connection to a commercial or medical power supply is required, for personal safety, it is necessary to use an isolated power supply, and in some cases, a reinforced isolated power supply. should be used.

④ For remote industrial communication power supply, in order to effectively reduce effect of ground potential difference and wire connection noise, an isolated power supply is generally used to supply power to each communication node separately.

⑤ Non-isolated power supply is used in cases where battery power is used and battery life is strictly required.

Four, electrical power

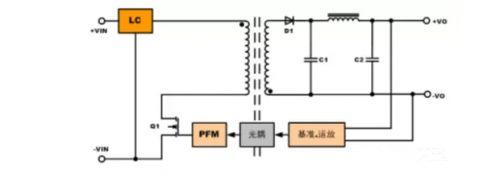

Power supply insulation withstand voltage is also called dielectric strength in national standard GB-4943. This GB-4943 standard is information equipment security standard that we often talk about, and it is national standard for preventing personnel from physical and electrical damage, including protecting people from electric shock, physical damage, explosion and other damage. The following figure is a block diagram of an isolated power supply.

Isolated power supply block diagram

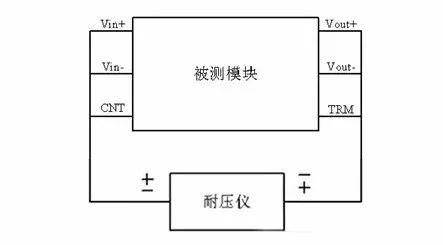

As an important indicator of power supply of module, standard also provides test methods related to insulation and withstand voltage. The equipotential bonding test is usually used for simple tests. The connection diagram looks like this:

Insulation withstand voltage test diagram

Test method:

Set withstand voltage meter voltage to specified withstand voltage value, current to specified leakage current value, and time to specified test time value;

Turn on withstand voltage meter to start test and start applying pressure. During specified test time, there should be no breakdown or arcing in module.

Attention should be paid to selecting a suitable welding temperature for power module during testing to avoid re-welding and damage to power module.

5. Advantages and disadvantages of isolated and non-isolated power supply

Advantages and disadvantages of isolated and non-isolated power supply

By understanding advantages and disadvantages of isolated and non-isolated power supplies, we can see that each has its own advantages. For some commonly used options for integrated power supplies, we can follow following evaluation conditions:

In safety applications where AC/DC connection to mains or medical power is required, an isolated power supply must be used for personal safety, and in some cases a reinforced isolated power supply. power supply must be used.

The module power supply isolation voltage generally used is not very high, but higher isolation voltage can ensure that module power supply has lower leakage current, higher safety and reliability, and better EMC performance. current industry-wide insulation voltage level exceeds 1500 VDC.

Related

- How to choose a switching power supply - isolated or non-isolated

- Four ways to reduce the output "ripple and noise" of a switching power supply

- Explain in detail why a switching power supply should be connected to an equivalent load.

- When designing a power supply, how to consider choice of topology?

- Finally, it becomes clear that process of obtaining switching losses of a MOSFET in a switching power supply

- Analysis of damping RC circuit of a switching power supply "haberdashery"

- Detailed analysis of the "various protection schemes" of a switching power supply

- Analysis of various losses inside a switching power supply from 4 aspects

- How to choose a suitable power chip, do you know this?

- The principle of operation of a switching power supply "Exchange of haberdashery" and a circuit diagram

Hot Posts

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

- What is drowning in gold? Why Shen Jin?

- This is a metaphor for EMI/EMS/EMC that can be understood at a glance.

- How many types of pads have you seen in PCB design?

- Summary of Common PCB Repair Techniques

- What is three anti-paint? How to use it correctly?

- Knowing these rules, you will not get confused looking at circuit diagram.

- How to make anti-interference PCB design?

- Can diodes do this?