Location:Home Page > Archive Archive

General PCB debugging skills

2023-04-07【Archive】

Whether it's a board made by someone else or a PCB designed and manufactured by you, first thing to do when you receive it is to check for board integrity such as tinning, cracks, shorts, cliffs. circuits, and drilling. The role is more strict, then you can by way check resistance between power supply and ground wire.

Under normal circumstances, a homemade board will be installed with components after tinning is completed, and if anyone does, it's just a tinned PCB with holes. Install components.

Some people have a lot of information about PCB they have designed, so they like to install all components in one go before testing. In fact, it's better to do it in parts.

PCB debugging in progress

Debugging a new circuit board can begin with power supply. It's safest to install a fuse and then plug in power supply (it's best to use a regulated power supply just in case).

Use an adjustable power supply to set overcurrent protection current, and then slowly increase voltage of regulated power supply. This process is to control input current, input voltage, and output voltage of board.

When voltage is adjusted upwards, there is no overcurrent protection, and output voltage is normal, which means there is no problem with board's power supply. If normal output voltage or overcurrent protection is exceeded, then you need to check cause of problem.

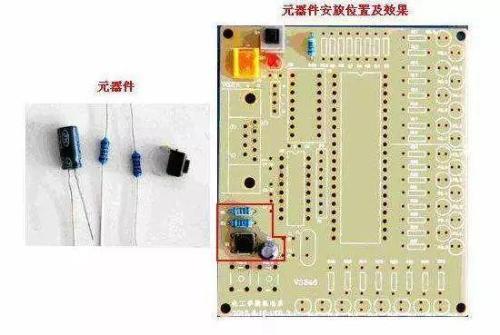

Installing PCB components

While debugging, Install modules incrementally and follow steps above to check each time you install one or more modules, which will help you avoid some more hidden errors early in your design. , or Incorrect installation of components, which will burn out components due to overcurrent.

If installation process fails, you can usually use following troubleshooting methods:

Troubleshooting Method 1: Measuring Voltage

Voltage measurement method

When overcurrent protection is triggered, do not rush to disassemble components, first check voltage on power pins of each chip to make sure that it is within normal limits. After that, reference voltage, operating voltage, etc. are successively determined.

For example: when silicon triode is on, voltage at BE junction will be about 0.7V, and voltage at CE junction is usually no more than 0.3V.

During testing, it is found that voltage of BE junction is higher than 0.7V (special Darlington type transistors are excluded here), then BE junction can be open. Check voltage at each point in turn to troubleshoot.

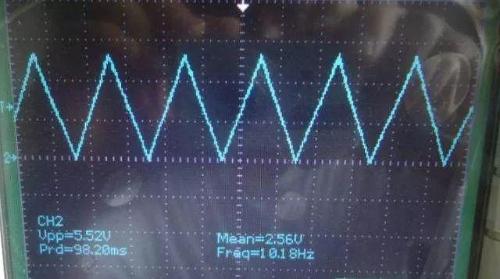

Troubleshooting 2: Signal Injection

Signal input method

The signal input method is more troublesome than voltage measurement. After signal source is sent to input terminal, we need to measure waveforms of each subsequent point in turn to find fault point from waveform.

Of course, you can also use tweezers to locate input jack. The method is to touch input jack with tweezers and then observe response of input jack. Typically, this method is used in case of audio and video. amplifier circuits (Note: hot floor circuits and do not use this method for high voltage circuits, as it may cause electric shock).

This method determines that previous level is normal and last level is responding, so error is not at last level, but at first level.

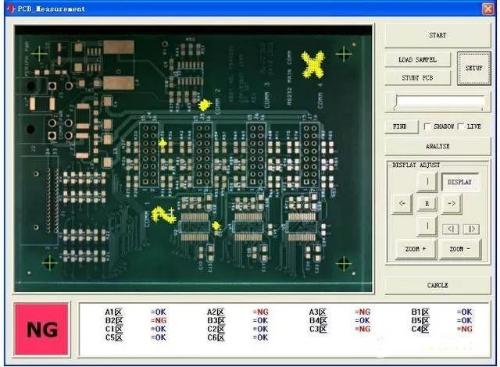

Third troubleshooting method: Other

Machine for checking appearance of printed circuit boards

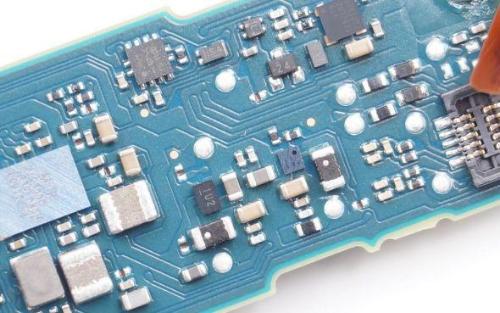

The above two methods are relatively simple and straightforward. In addition, it is often said that engineers such as vision, smell, hearing, touch, etc. must have some experience in order to detect problems.

As a rule, "look" means not to look at state of testing device, but to see if appearance of components is complete; Components, when damaged, emit an unpleasant burning smell.

"Listening" is mainly for listening to see if sound of board is normal in working condition; about "touching" one should not touch whether components are weakened, but whether to feel temperature of components. It is normal to do this manually, for example, in operation, cold components generate heat and heat generating components are very cold. In process of touching, do not pinch it directly with your hands, in case temperature is too high to burn your hands.

Related

- General PCB debugging skills

- Switching Power Supply PCB Design Skills

- What does inside of a multilayer PCB look like? Three-dimensional general analysis of design process of high-quality printed circuit boards

- Should PCB trace angle be 90°? — Jumping guide to PCB layout pit

- Pay attention to PCB vias

- Summary of Common PCB Repair Techniques

- PCB puzzle, these few special rules!

- How to make anti-interference PCB design?

- Six Methods for Testing PCB Short Circuits

- With these two schematics, PCB design is easy!

Hot Posts

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

- What is drowning in gold? Why Shen Jin?

- This is a metaphor for EMI/EMS/EMC that can be understood at a glance.

- How many types of pads have you seen in PCB design?

- Summary of Common PCB Repair Techniques

- What is three anti-paint? How to use it correctly?

- Knowing these rules, you will not get confused looking at circuit diagram.

- How to make anti-interference PCB design?

- Can diodes do this?