Location:Home Page > Archive Archive

The most complete test of iron 5 processes, one less will not work

2023-04-14【Archive】

Hardware detection before power on

When PCB is soldered, when checking whether PCB can work normally, usually do not apply power directly to PCB, but following steps are taken to make sure at each step before power on. Late.

1. Is connection established correctly. Checking circuit diagram is very important. The first inspection is to see if power supplies of chip and network nodes are correctly labeled. At same time, it is also necessary to pay attention to whether network nodes overlap. Another important point is packaging of original component, packaging model and output order of packaging, packaging can not use top view, remember! Especially for packages without a pin. Check for correct wiring, including incorrect wiring, missing wiring, and multiple wiring.

There are usually two ways to check lines:1) Check installed lines according to circuit diagram, and check installed lines one by one in a certain order according to circuit connection; >2) According to actual diagram, check circuit diagram and check line with one component in center. Check connection of each pin of component once and check if each place exists on circuit diagram. To prevent errors, lines that have been tested should usually be marked on wiring diagram. It is best to test buzzer with a dial multimeter resistance block and measure component's pins directly, so that bad wiring can be found at same time.

2. Short circuit in power supply. Do not turn on power before debugging, use a multimeter to measure input resistance of power supply, this is a necessary step! Short circuiting power supply can cause power supply to burn out or be more serious. When it comes to power supply, a 0 ohm resistor can be used as a debugging method. Do not solder resistor before turning on power, check power supply voltage is normal, and then solder resistor on PCB to supply power to unit at rear, so as not to burn chip of rear unit due to abnormal supply voltage. when power is turned on. Add protection schemes to circuit design, such as using fuses and other components.

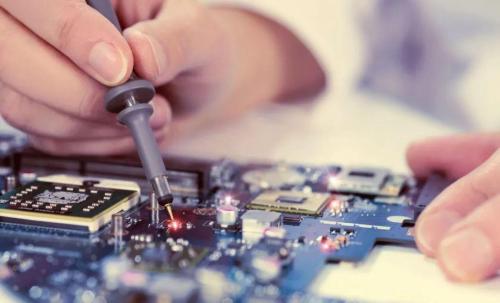

3. Installing components. This is mainly to test polarized components such as light emitting diodes, electrolytic capacitors, rectifier diodes, etc., and to match contacts of triode. For triodes, location of pins of different manufacturers with same function is also different, it is best to check with a multimeter.

Perform an open circuit and short circuit test first to ensure that no short circuit occurs after power is turned on. If checkpoints are setThat's right, you can get twice result with half effort. The use of 0 ohm resistors is also sometimes useful for testing high speed circuits.

The power-on test can only be run after above hardware test before power-on is completed.

Power-on detection

1. Power-on observation: Do not rush to measure electrical performance after power-on, but observe whether there is any abnormality in circuit, such as whether there is smoke or abnormal smell, and touch outer packaging of integrated circuit with your hands whether it is hot etc. If there is an abnormal phenomenon, power should be turned off immediately, and power should be turned on again after troubleshooting.

2. Static debugging: Static debugging usually refers to a DC test under condition that no input signal is added or only a fixed level signal is added. The point potential is compared with theoretical estimated value, combined with analysis of circuit principle, to determine whether working state of DC circuit is normal, and in time to detect damaged or critical components in circuit. By replacing components or by adjusting circuit parameters, operating condition of DC circuit can meet design requirements.

3. Dynamic Debugging: Dynamic debugging is based on static debugging. Appropriate signals are added to input end of circuit, and output signals of each breakpoint are detected in sequence. according to direction of signal flow. If any abnormal phenomenon is found, analyze cause, troubleshoot, and then debug until requirements are met.

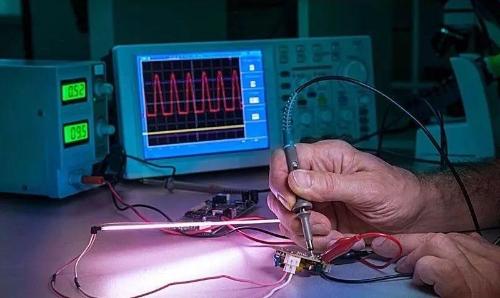

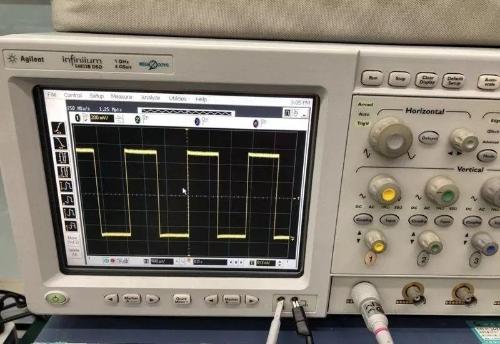

In process of testing, you can not rely on your feelings, but always use tools for observation. When using an oscilloscope, it is best to set oscilloscope's input mode to "DC" block. With DC coupling mode, you can simultaneously observe AC and DC components of measured signal. Through debugging, finally check whether various indicators of function block and whole machine (such as signal amplitude, waveform, phase ratio, gain, input and output impedance, etc.) meet design requirements, and suggest additional ones if necessary. options. reasonable correction of circuit parameters.

Other electronic debugging work

1. Determine breakpoint: According to principle of custom system, outline debugging steps and measurement methods, define breakpoint, mark position on drawing and board, and make debug data record form wait.

2. Set up a debugging workbench. The workbench is equipped with necessary debugging tools, and their location should be easy to use and easy to observe. Special Reminder: When crafting and debugging, workbench must be clean and tidy.

3. Select a Meter: for a hardware circuit, Meter must be selected by system being tuned, and accuracy of Meter must be better than that of system under test; for debugging software, it must be equipped with microcomputer and processor.

4. Debug Sequence: The debug sequence of electronic circuits is usually performed according to direction of signal flow, and output of previously debugged circuit is used as input to next step to condition final correction.

5. General debugging: select digital circuit implemented by programmable logic device, input, debugging and loading of programmable logic device source file must be completed, and programmable logic device and analog circuit must be connected to system, general debugging and test results.

While debugging, carefully observe and analyze experimental phenomena and take notes to ensure the integrity and reliability of experimental data.

Precautions when debugging a schema

Adequate debug result depends a lot on scope of test and accuracy of test. In order to guarantee test results, it is necessary to reduce test error and improve test accuracy. To do this, we need to pay attention to following points:

1. Use tester's ground terminal correctly. Use an electronic tester with a ground terminal connected to chassis for testing. The common ground terminal must be connected to ground terminal of amplifier. An error was found as a result of check. According to this principle, when debugging emitter bias circuit, if Vce needs to be checked, two ends of instrument should not be directly connected to collector and emitter, but Vc and Ve should be measured with respect to ground respectively, and then two phases are reduced. If a dry battery multimeter is being used for testing, since two input leads of ammeter are floating, it can be connected directly between test points.

2. The input impedance of device used to measure voltage must be much greater than equivalent resistance of measuring point. If input impedance of tester is low, it will cause a shunt during measurement, resulting in large errors in test results.

3. The bandwidth of test instrument must be greater than bandwidth of circuit under test.

4. Choose right control point. When same meter is used for measurement, measurement point is different, and error caused by internal resistance of meter will be very different.

5. The method of measurement must be convenient and feasible. When you want to measure current in a particular circuit, you can usually measure voltage as much as possible instead of current, because you don't have to change circuit to measure voltage. If it is necessary to know current value of a certain branch, it can be obtained by measuring voltage at both ends of resistor on branch and converting it.

6. In process of debugging, it is necessary not only to carefully observe and measure, but also to record well. Recorded content includes experimental conditions, observed phenomena, measured data, waveform and phase relationship, etc. Only by comparing a large number of reliable experimental records with theoretical results, we can find problems in circuit design and improve design scheme.

Troubleshooting while debugging

You must carefully investigate cause of fault and do not remove or reinstall line if fault cannot be corrected. Because if this is a problem in principle, then even reinstalling will not solve problem.

1. General troubleshooting method

For a complex system, it is not easy to accurately find a fault among a large number of components and circuits. The overall process of diagnosing a malfunction starts from phenomenon of a malfunction, analyzes and evaluates through repeated tests, and gradually detects a malfunction.

2. Symptoms and causes of failure

1) Typical failure symptoms: There is no input signal to amplifier circuit, but there is an output signal. The amplifier circuit has an input signal but no output waveform, or waveform is abnormal. The series regulated power supply has no output voltage, or output voltage is too large to adjust, or output voltage stabilization performance is degraded, and output voltage is unstable. The oscillatory circuit does not oscillate, shape of oncoming signal is unstable, etc.

2) Cause of failure: The corrected product fails after a certain period of use, which may be due to damaged components, short circuit or disconnection, or changing conditions, etc.

3. Common troubleshooting methods

1) Direct observation method: Check correctness of choice and use of device, compliance of level and polarity of supply voltage with requirements; lack of connections and mutual collisions, etc. Is wiring faulty, is there a short circuit on circuit board, are resistors and capacitors burned or burst, etc. Turn on power and check if components are hot or smoke, no Is there a burning smell from transformer, Is filament of electron tube and oscilloscope tube bright, Is there high voltage sparking, etc.

2) Use a multimeter to check static operating point: of electronic circuit power supply system, semiconductor triode DC operating state and integrated unit (including components, device contacts, power supply voltage), and line resistance The values can be measured with a multimeter. When measured value is very different from normal value, fault can be found after analysis.

By way, rest point can also be determined from "DC" input of oscilloscope. The advantage of using an oscilloscope is that internal resistance is large, and working state of DC current and waveform of measured point can be seen at same time, as well as possible interference signals and noise voltages, etc., which is more convenient for error analysis.

3) Signal trace method: For various complex circuitsm, a signal with a certain amplitude and corresponding frequency can be connected to input terminal (for example, for multi-stage amplifiers, this can be used in Its input connector is connected to a sinusoidal signal f, 1000 Hz), use an oscilloscope from front stage to rear stage (or vice versa) and watch shape and amplitude change step by step. stage is abnormal, error is in this stage.

4) Comparison Method: When you suspect that there is a problem in a certain circuit, you can compare parameters of that circuit with same normal parameters (or current, voltage, waveform, etc.). ). .theoretical analysis) one by one Compare and find out abnormal situation in circuit, and then analyze and evaluate fault location.

5) Part replacement method: sometimes fault is hidden and not visible at first sight. For example, if you have an instrument of same model as defective instrument, you can replace , plug-in board, etc. to replace corresponding parts in defective instrument in order to narrow down area of the problem and find source of problem.

6) Workaround method: For parasitic oscillations, you can use a suitable capacitor, select a suitable test point, and temporarily connect a capacitor between test point and reference ground. dot , if oscillation disappears, this indicates that oscillation is generated near this or in previous circuit of cascade. Otherwise, look for him from behind and then move checkpoint. The shunt capacitor should be suitable and should not be too large if it can better eliminate harmful signals.

7) Short circuit method: is a method of temporarily short circuiting a part of a circuit for troubleshooting purposes. The short circuit method is most effective for checking for an open circuit. However, it should be noted that power supply (circuit) cannot be short-circuited.

8) Open circuit method: The open circuit method is most effective for short circuit testing. The open circuit method is also a method of progressively narrowing down range of suspected fault points. For example, if a regulated power supply is connected to a circuit with a fault, output current is too large, we use method of disconnecting a certain branch of circuit to check for a fault. If current returns to normal after a branch is switched off, a fault occurs in that branch.

In real-world debugging, there are many ways to find cause of a crash, and above are just a few commonly used methods. The use of these methods can find point of failure with one method for simple faults, but for more complex faults, it is necessary to use several methods that complement each other and interact with each other, whichto find a point of failure. In general, usual troubleshooting practice is:

1) Eliminate obvious deficiencies through direct observation.

2) Check the static set point with a multimeter (or oscilloscope).

3) The signal trace method is a simple and intuitive method that is generally applicable to various circuits and is widely used in dynamic debugging.

Related

- The most complete test of iron 5 processes, one less will not work

- The most complete knowledge in history of uninterruptible power supply UPS

- Diode switching circuit and troubleshooting, one complete wizard

- List of 5 Most Practical Network Analysis Techniques! must watch

- What is a magnetic sensor? The most common types of magnetic sensors and their applications

- Still foolishly setting silkscreen bit numbers of PCB components one by one?

- Countdown of 8 most commonly used diodes

- 44 types of practical schemes, you will master, you will know everything!

- Knowing these rules, you will not get confused looking at circuit diagram.

- Super practical! The 10 Most Commonly Used Power Supply Design Formulas

Hot Posts

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

How to distinguish induction from leakage, we will teach you three tricks! Ordinary people can also learn super practical

- What is drowning in gold? Why Shen Jin?

- This is a metaphor for EMI/EMS/EMC that can be understood at a glance.

- How many types of pads have you seen in PCB design?

- Summary of Common PCB Repair Techniques

- What is three anti-paint? How to use it correctly?

- Knowing these rules, you will not get confused looking at circuit diagram.

- How to make anti-interference PCB design?

- Can diodes do this?